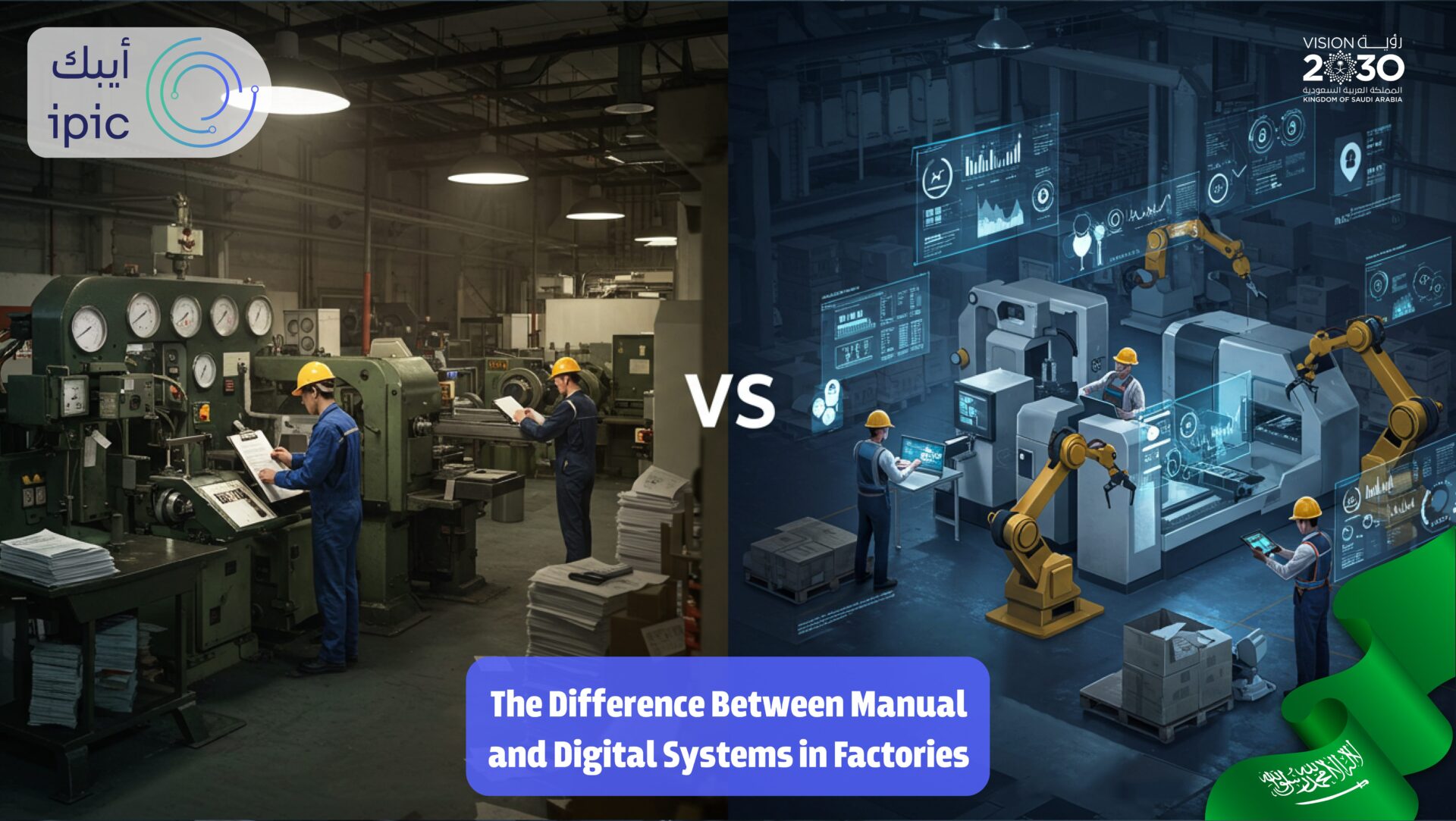

The Difference Between Manual and Digital Systems in Factories

In the modern manufacturing world, the industry has undergone a dramatic transformation from traditional manual systems to advanced digital solutions. This shift is a crucial part of the movement towards Industry 4.0, which helps factories enhance efficiency, improve productivity, and reduce costs. But what is the actual difference between manual and digital systems in factories? How does this difference affect daily operations?

1. Data Management and Storage

Manual Systems

In manual systems, data is recorded manually by workers, such as production logs, downtime, product quality, and maintenance operations. This can lead to human errors, delays in documenting information, and slow decision-making.

Digital Systems

In digital systems, data is automatically collected using smart sensors and advanced measuring devices. Data is stored in ERP systems or MES (Manufacturing Execution Systems), making it easy to track and analyze in real-time. This enhances the ability to make data-driven decisions with accurate insights.

2. Production Efficiency

Manual Systems

Manual systems require significant human intervention to monitor production and execute operations, increasing the chance of errors or slowdowns in production. Additionally, supervisors find it challenging to monitor all processes in real-time.

Digital Systems

With digital systems, many processes on the production line are automated. MES systems provide real-time oversight of operations, allowing quick identification of issues that could affect production. Resources are allocated more efficiently, ensuring smooth operations.

3. Predictive Planning and Forecasting

Manual Systems

Manual systems often lack the capability to predict future production needs. Employees rely on estimates and historical data that may not be accurate, making it difficult to plan for resources and orders.

Digital Systems

Digital systems enable the use of predictive analytics and artificial intelligence to provide a clear view of future production requirements. These systems can predict potential issues such as machine breakdowns or raw material shortages, allowing for proactive planning.

4. Performance Tracking and Flexibility

Manual Systems

In manual systems, supervisors must manually collect and review data periodically to assess factory performance. This is time-consuming and requires extra effort. Additionally, adjusting operations in response to emergencies or sudden market changes is difficult.

Digital Systems

Digital systems allow for real-time performance tracking using smart dashboards. The systems can easily be adapted to meet changing needs, such as rescheduling operations or adjusting quality parameters quickly and efficiently. This makes factories more flexible and responsive to changes in the market.

5. Communication and Coordination Between Departments

Manual Systems

In manual systems, communication between different departments tends to be informal and often slow. It requires continuous interaction between teams, which increases the likelihood of errors or delays.

Digital Systems

Digital systems integrate departments via connected ERP systems, ensuring smooth information flow between production, sales, and inventory teams. This enhances collaboration and reduces errors, as information is exchanged more quickly and accurately.

6. Security and Data Protection

Manual Systems

Manual systems depend on paper records or unprotected servers for data storage, which exposes the information to the risk of loss or tampering. Additionally, relying on human operators introduces various security gaps.

Digital Systems

Digital systems provide high levels of security using encryption and multi-factor authentication to protect data. These systems allow continuous monitoring of access, minimizing the risks of data loss or manipulation.

7. Cost

Manual Systems

While manual systems might have a lower initial cost, they tend to raise operational costs in the long term. More personnel are needed for monitoring and documentation, and human errors can lead to additional costs.

Digital Systems

Digital systems require a higher initial investment but result in lower operational costs over time. Automation and process optimization lead to significant cost savings, while waste reduction and improved productivity contribute to financial benefits.

Conclusion

While manual systems were widely used in the past, digital systems have become the cornerstone of Industry 4.0 in the modern era. Through automation, predictive analytics, and seamless inter-departmental communication, digital systems offer greater efficiency, higher accuracy, and improved performance. Therefore, it is essential for factories aiming to enhance productivity and achieve technological excellence to adopt these digital systems to stay competitive and ensure long-term success.